An increasing number of power electronics products are taking advantage of a growing trend in the printed circuit board industry.

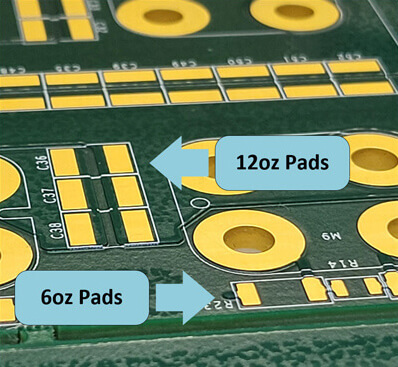

PCBs with 3oz or more of finished copper in the inner and/or outer layers are defined as Heavy Copper. Our manufacturing facilities allow Heavy Copper boards to be produced up to 32 layers.

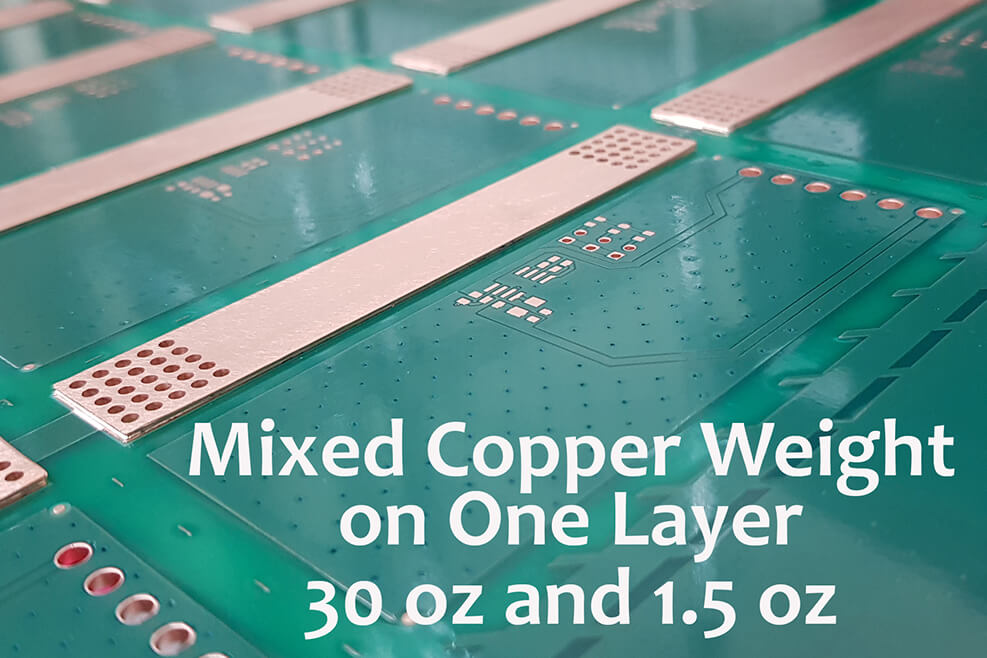

We also have the capability for Extreme Heavy Copper - up to 30oz per layer for 2 layer applications.

Heavy Copper and Extreme Heavy Copper PCB's offer benefits such as:

DK-Daleba can help you with design procedures for Heavy Copper. We can offer track and gap spacing guidance, current-carrying details and best practice guidelines for heavy copper circuits.

| Property | Weight (oz) | Thickness (mm) |

|---|---|---|

| Standard Copper | ½ - 4 | 0.018 - 0.14 |

| Heavy Copper | 5 - 15 | 0.175 - 0.525 |

| Extreme Heavy Copper | 15 - 70 | 0.525 - 2.45 |

| Mixed Copper Weights | 1 ½ oz and 30 oz on the same layer (Double Sided) | 1 ½ oz and 30 oz on the same layer (Double Sided) |

Applications: