Our dedicated engineers will focus on finding the best PCB solutions for your needs. Our engineering services include design for manufacture. We have engineers in the UK and also in our Asia factories to ensure every part of the supply process is managed.

Our EngineersBespoke PCB stock management is our speciality, which means we'll find solutions for every requirement. Our stock management team will monitor your usage against forecasted levels to ensure that production lines are kept running.

Manage StockStress-free, on time, and without any of the headaches that logistics can cause: that's how we deliver! Our range of shipment options ensure you receive your order in the right place and at the right time, anywhere in the world.

Logistic OptionsDaleba is a UK PCB supplier and global market leader with almost endless technical capabilities. We focus on building personal, dedicated relationships to offer the best advice and PCB solutions. We pride ourselves on our ability to adapt to the needs of both the industry and individual specifications. Our experienced engineers can offer technical support and consult on complex design and manufacturing issues. We have an unparalleled supply chain meaning we can accommodate unique client requirements with a variety of materials and technologies. We offer competitive pricing for small and volume production runs through cost-saving production processes. Quick turnarounds and the capacity to accommodate last-minute demands are no problem and with 60 years of experience, we have the capability and know-how to deliver the right product time and time again.

Our ProductsWe believe our excellent reputation is because of our high-quality service and products. We provide a Total Supply Management solution, with experienced and dedicated team members who will deal with you on everything from your initial enquiry, quotations, engineering, quality, logistics and other key systems that all come together to ensure a seamless PCB supply service.

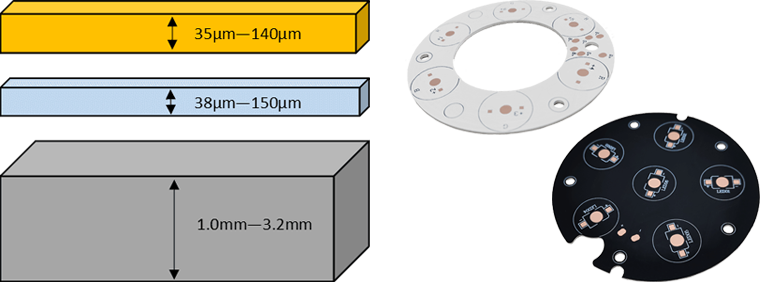

Quality ManagementThe advantage of using metal clad material for PCB production as opposed to more traditional materials such as FR4 and CEM is down to the efficient removal of heat. The dielectric insulating material in metal clad materials is designed to have a much superior thermal conductivity than that of FR4, Most materials have a conductivity ranging from 1W/m-K to 9W/m-K, allowing for efficient heat removal.

All About MCPCBs

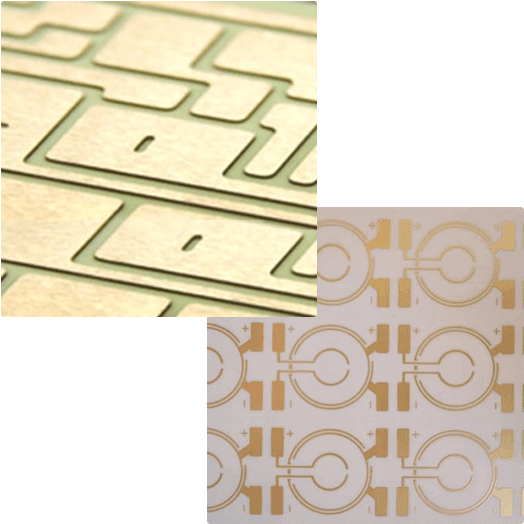

Ceramic PCBs have received enormous attention from the industry as an effective solution to a range of electronic issues. The superior Thermal Conductivity of ceramics, to 180W/mK., being the leading reason that more and more industries are turning to ceramics for their PCB design.

Heat dissipation is the key advantage that Ceramic has over more conventional materials such as FR4 and Metal Clad PCBs. With components being placed directly on the boards, and no isolation layer, the flow of heat through the boards is far more efficient.

In addition to this, Ceramic material can withstand high operating temperatures (over 800°C) and has a very low CTE (Coefficient of Thermal Expansion), allowing for additional compatibility options for circuit design.

Daleba specialises in Alumina Oxide (Al2O3), Aluminium Nitride (AlN) and Silicone Nitride (SiN) using Direct Bonded Copper (DBC), Direct Plated Copper (DPC) and Active Metal Brazing (AMB) technologies.

All About Ceramic PCBs

Daleba offer a range of Thermal Interface Materials and EMI/RFI Shielding products under our brand name:

The EMI Thermal range of EMI/EMC/RFI shielding products in conjunction with thermal interface materials (TIM) have been developed to meet the most demanding shielding and thermal requirements. Wherever you are in Europe we can provide the full range of EMI Thermal products. Our highly capable and knowledgeable European distributors will be pleased to assist with enquiries. EMI materials can be supplied in sheets, mesh and extrusions, thermal interface material in sheets or rolls.

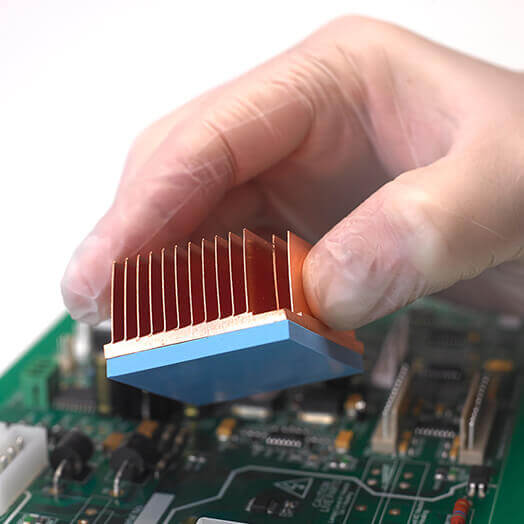

The requirement to drive electronic components harder and faster, at higher power, from smaller packages means they are running hotter - and too much heat is a component killer. In the battle to get heat away from electronic components, Thermal Interface Material is a simple but very effective, cost-effective solution that significantly improves the transfer of heat from component to heat sink.

From our EMI Thermal product range Thermal Interface Materials are the most popular products we offer. LED's, Electric vehicle motor drives, audio systems, automotive lighting, braking and steering systems… these are all examples of applications where TIM is used to remove air gaps as part of effective thermal management to ensure reliability, performance and to prevent component failure.

0

Owned Factories

0

PCB's In Stock

0

Engineers

0

Years Experience

Please leave your contact details below and one of our specialists will be in touch as soon as possible. Or directly request a quote online.

Get a Quote