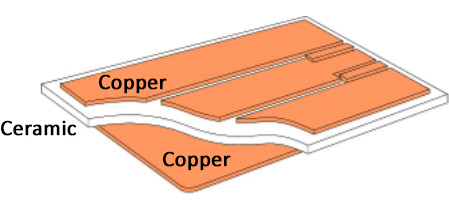

The evolution of technology has seen a considerable increase in the use of electronics with a continuous and growing market requirement to package products into smaller devices and handle thermal issues from modern components. This need demonstrates an increase in demand for more robust solutions. Modern materials and solutions are needed to handle both high Thermal Conductivity and high operating temperatures. Ceramic solutions for PCBs with semiconductors using materials like Silicon Carbide and Gallium Nitride are becoming commonplace. These materials can operate at temperatures up to 400°C; a temperature requirement that is far too high for any substrate apart from ceramic.

Very often a design is moved from FR4 to aluminium IMS boards when high temperatures are involved. However, the maximum operating temperature (MOT) of 155°-160° and thermal conductivity of 8-19W/mK for IMS is sometimes insufficient to manage an incumbent thermal issue. With a ceramic panel, components are placed directly on the board, with no isolation layer, which in turn makes the flow of heat far more efficient. Depending on your choice of a ceramic substrate, engineers are typically finding thermal conductivity to reach 24-180W/mK, coupled with a very low CTE (Coefficient of Thermal Expansion) and of course a high MOT. This solution creates an ideal choice for many projects that need to deal with high operating temperatures efficiently.

Significant temperatures require strong R&D

AT DK-Daleba, we very much lead the way in ceramic substrates, and the demand is increasing year-on-year for more robust solutions. Although we are restricted by non-disclosure agreements preventing us revealing specific project details, DK-Daleba is working with some of the largest Technology brands on the planet to help them decipher these more robust solutions. Ceramics accounts for many of our R&D projects we are working on currently with these brands.

Although we cannot reveal the global technology companies we are working with, one particular customer required a circuit to function at 600°C, with a further requirement for the substrate to be used in a vacuum, with no outgassing. The design required this specification and to allow for a maximum operating temperature of 800°C, with an inert nature of the substrate to produce no outgassing. An Al2O3 Alumina Oxide was the ideal choice for their project.

Ceramics also offer low signal loss and microelectronics build options. Thermal issues are at the forefront though so if you have a requirement or project that requires high operating temperatures, our team at DK-Daleba are experts in the field of designing solutions utilising these specialist materials. Our R&D team can work with your specification to help provide a robust and cost-effective solution.

Date : 23-11-2020